Chromium Picolinate Cr 0.2% Red Powder for Poultry Organic Intermediate Product CAS 14639-25-9

As a leading enterprise in the production of animal trace elements in China, SUSTAR has received widespread recognition from customers both domestically and internationally for its high-quality products and efficient services. The chromium picolinate produced by SUSTAR not only comes from superior raw materials but also undergoes more advanced production processes compared to other similar factories.

Product Efficacy

Chromium picolinate (Cr 0.2%), 2000mg/kg. Suitable for direct addition to pig and poultry feed. Applicable for complete feed factories and large-scale farms. Can be directly added to commercial feed.

- NO.1 Highly bioavailable

- It is organic source of chromium for use in swine, beef, dairy cattle and broilers.

- NO.2 Highly glucose utilization in animals

- It could potentiate the action of insulin and improve glucose utilization in animals.

- NO.3 Highly reproduction,growth/performance

Manufacturing Technique

- No.1 The raw material and dispersant are mixed in proportion;

- No.2 High precision graded ultrafine grinding;

- No.3 Multistage multigradient dilution;

- No.4 High precision inspection of semi-finished products and finished products;

- No.5 Health indicators: High frequency, full coverage quality control.

Indicator

- Chemical name:Chromium Picolinate

Formula:Cr(C6H4NO2)3

Molecular weight:418.3

Appearance: White with lilac powder, anti-caking ,good fluidity

Cr 0.2% Physical and Chemical indicator:

|

C18H12CrN3O6 |

≥1.6% |

|

Cr |

≥0.2% |

|

Arsenic |

≤5mg/kg |

|

Lead |

≤10mg/kg |

|

Cadmium |

≤2mg/kg |

|

Mercury |

≤0.1mg/kg |

|

Moisture |

≤2.0% |

|

Microorganism |

None |

Cr 12% Physical and Chemical indicator:

|

Cr(C6H4NO2)3 |

≥96.4% |

|

Cr |

≥12.2% |

|

Arsenic |

≤5mg/kg |

|

Lead |

≤10mg/kg |

|

Cadmium |

≤2mg/kg |

|

Mercury |

≤0.1mg/kg |

|

Moisture |

≤0.5% |

|

Microorganism |

None |

Applications

- Application of animal nutrition: Pig

- No.1 Improve the ability of weaning piglets to resist stress and enhance immunity;

- No.2 Improve reproductive performance of sows;

- No.3 Promote growth of fattening pigs;

- No.4 Improve meat quality

Function

Currently on the market sales of chromium picolinate,the chromium picolinate content ≥98.0%, total chromium was 12.2%~12.4%, fineness indexes of 150 microns(100 mesh) by 90%. Because of the minimal amount of chromium picolinate added into the feed, the product can not be directly added into the feed (including premixed feed),otherwise the mixture will be uneven.

1.Trivalent Chromium is the safe ,ideal chromium sources,it has biological activity , and also works together with insulin produced by the pancreas to metabolize carbohydrates. It promotes lipid metabolism.

2.It is organic source of chromium for use in swine, beef, dairy cattle and broilers.It eases the stress reaction from nutrition, environment and metabolism, reducing the production loss.

3.Highly glucose utilization in animals.It could potentiate the action of insulin and improve glucose utilization in animals.

4.Highly reproduction,growth/performance

5. Improve carcass quality, reduce back fat thickness,enhance lean meat percentage and eye muscle area.

6. Improve the farrowing rate of sow herd, the egg production rate of layer chicken, and the milk production of dairy cattle.

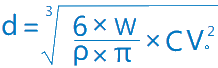

According to Poisson Distribution Theory,the particle size and mixing uniformity of microelement additives have the following relationship:

D:particle size of trace components,um;

W:daily intake of trace components of animals,g;

P:specific gravity of trace components,g/um3;

CVo:given coefficient of variation.

Calculation results:

| Animal | Nutrient

levels(mg/kg) |

Daily intake

(g/each day) |

CV(%) | Particle size(um) | The corresponding mesh | Adjustable mesh |

| Piglets after

weaning |

0.2 | 200 | 5 | 99 | 163 | 200 |

| 1-week old

broiler |

0.2 | 16 | 5 | 42 | 357 | 400 |

|

Grass carp young fish |

0.2 | 8 | 5 | 34 | 431 | 500 |

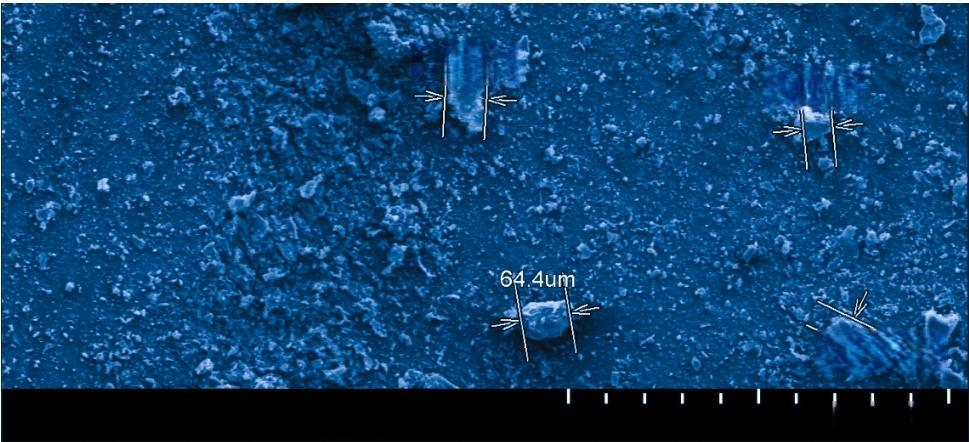

Therefore,the chromium picolinate sold on the market must be ultrafine crashed to ensure that when added to the feed,the product can meet the requirements of mixing uniformity for particle size.

The advanced ultrafine crashing technology adopted by our company can control the fineness with high precision and can be controllable and adjustable within the range of 300~ 2000 mesh.

In the production process of ultrafine chromium picolinate,the first step is to pulverize chromium picolinate into ultrafine powder,then add the carrier for adsorption and dilution, and the carrier's fine degree is about 80~200 mesh.Detect the particle size of chromium picolinate after ultrafine crashing and dilution,which can be observed under the electron microscope.

In addition,the content of chromium picolinate should be determined by the liquid phase method, so that the test results can be assured of organic chromium(chromium picolinate).

Top Choice of International Grop

Sustar group has decades-long partnership with CP Group, Cargill, DSM, ADM,Deheus ,Nutreco,New Hope ,Haid,Tongwei and some other TOP 100 big feed company.

Our Superiority

A Reliable Partner

Research and development capabilities

Integrating the talents of the team to build Lanzhi Institute of Biology

In order to promote and influence the development of livestock industry at home and abroad, Xuzhou Animal Nutrition Institute , Tongshan District Government, Sichuan Agricultural University and Jiangsu Sustar, the four sides established Xuzhou Lianzhi Biotechnology Research Institute in December 2019.

Professor Yu Bing of Animal Nutrition Research Institute of Sichuan Agricultural University served as the dean, Professor Zheng Ping and Professor Tong Gaogao served as the deputy dean. Many professors of Animal Nutrition Research Institute of Sichuan Agricultural University helped the expert team to accelerate the transformation of scientific and technological achievements in the animal husbandry industry and promote the development of the industry.

As a member of the National Technical Committee for Standardization of Feed Industry and the winner of China Standard Innovation Contribution Award, Sustar has participated in drafting or revising 13 national or industrial product standards and 1 method standard since 1997.

Sustar has passed the ISO9001 and ISO22000 system certification FAMI-QS product certification, obtained 2 invention patents, 13 utility model patents, accepted 60 patents, and passed the "Standardization of intellectual property management system", and was recognized as a national-level new high-tech enterprise.

Our premixed feed production line and drying equipment are in the leading position in the industry. Sustar has high performance liquid chromatograph, atomic absorption spectrophotometer, ultraviolet and visible spectrophotometer, atomic fluorescence spectrophotometer and other major testing instruments, complete and advanced configuration.

We has more than 30 animal nutritionists, animal veterinarians, chemical analysts, equipment engineers and senior professionals in feed processing, research and development, laboratory testing, to provide customers with a full range of services from formula development, product production, inspection, testing, product program integration and application and so on.

Quality inspection

We provide test reports for each batch of our products, such as heavy metals and microbial residues. Each batch of dioxins and PCBS complies with EU standards. To ensure safety and compliance.

Assist customers to complete the regulatory compliance of feed additives in different countries, such as the registration and filing in the EU, USA, South America, Middle East and other markets.

Production Capacity

Main product production capacity

Copper sulfate-15,000 tons/year

TBCC -6,000 tons/year

TBZC -6,000 tons/year

Potassium chloride -7,000 tons/year

Glycine chelate series -7,000 tons/year

Small peptide chelate series-3,000 tons/year

Manganese sulfate -20,000 tons /year

Ferrous sulfate-20,000 tons/year

Zinc sulfate -20,000 tons/year

Premix (Vitamin/Minerals)-60,000 tons/year

More than 35 years history with five factory

Sustar group has five factories in China ,with annual capacity up to 200,000 tonns, covering totally 34,473 square meters,220 employees.And we’re an FAMI-QS/ISO/GMP certified company .

Customized Services

Customize Purity Level

Our company has a number of products have a wide variety of purity levels, especially to support our customers to do customized services, according to your needs. For example, our product DMPT is available in 98%, 80%, and 40% purity options; Chromium picolinate can be provided with Cr 2%-12%; and L-selenomethionine can be provided with Se 0.4%-5%.

Custom Packaging

According to your design requirements, you can customize the logo, size, shape, and pattern of the outer packaging

No one-size-fits-all formula? We tailor it for you!

We are well aware that there are differences in raw materials, farming patterns and management levels in different regions. Our technical service team can provide you with one to one formula customization service.

Success Case

Positive Review

Various Exhibitions we Attend