Trace Elements Market Analysis

I,Analysis of non-ferrous metals

Week-on-week: Month-on-month:

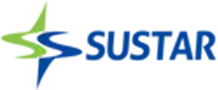

| Units | Week 1 of November | Week 2 of November | Week-on-week changes | October average price | As of November 14Average price | Month-on-month change | Current price as of November 18 | |

| Shanghai Metals Market # Zinc ingots | Yuan/ton |

22444 |

22522 |

↑78 |

22044 |

22483 |

↑439 |

22320 |

| Shanghai Metals Market # Electrolytic Copper | Yuan/ton |

86155 |

86880 |

↑725 |

86258 |

86518 |

↑260 |

86005 |

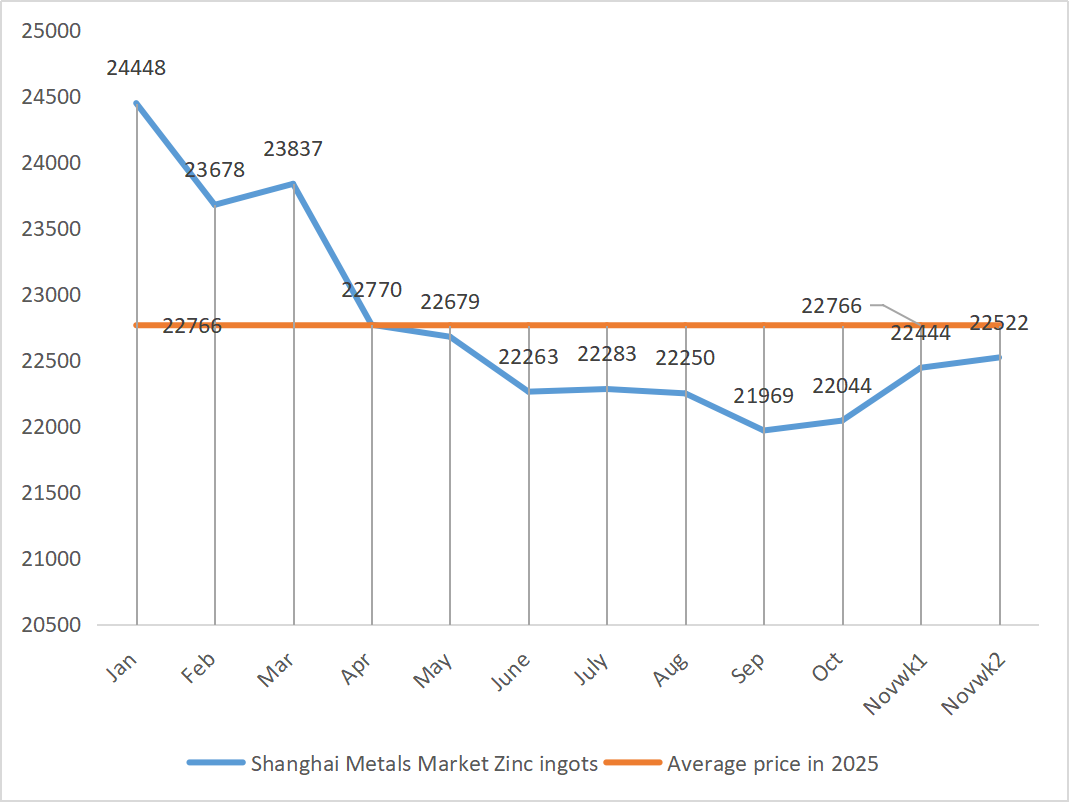

| Shanghai Metals AustraliaMn46% manganese ore | Yuan/ton |

40.45 |

40.55 |

↑0.1 |

40.49 |

40.50 |

↑0.01 |

40.55 |

| The price of imported refined iodine by Business Society | Yuan/ton |

635000 |

635000 |

- |

635000 |

635000 |

635000 |

|

| Shanghai Metals Market Cobalt Chloride(co≥24.2%) | Yuan/ton |

105000 |

105000 |

- |

101609 |

105000 |

↑3391 |

105000 |

| Shanghai Metals Market Selenium Dioxide | Yuan per kilogram |

110 |

114 |

↑4 |

106.91 |

112 |

↑5.91 |

115 |

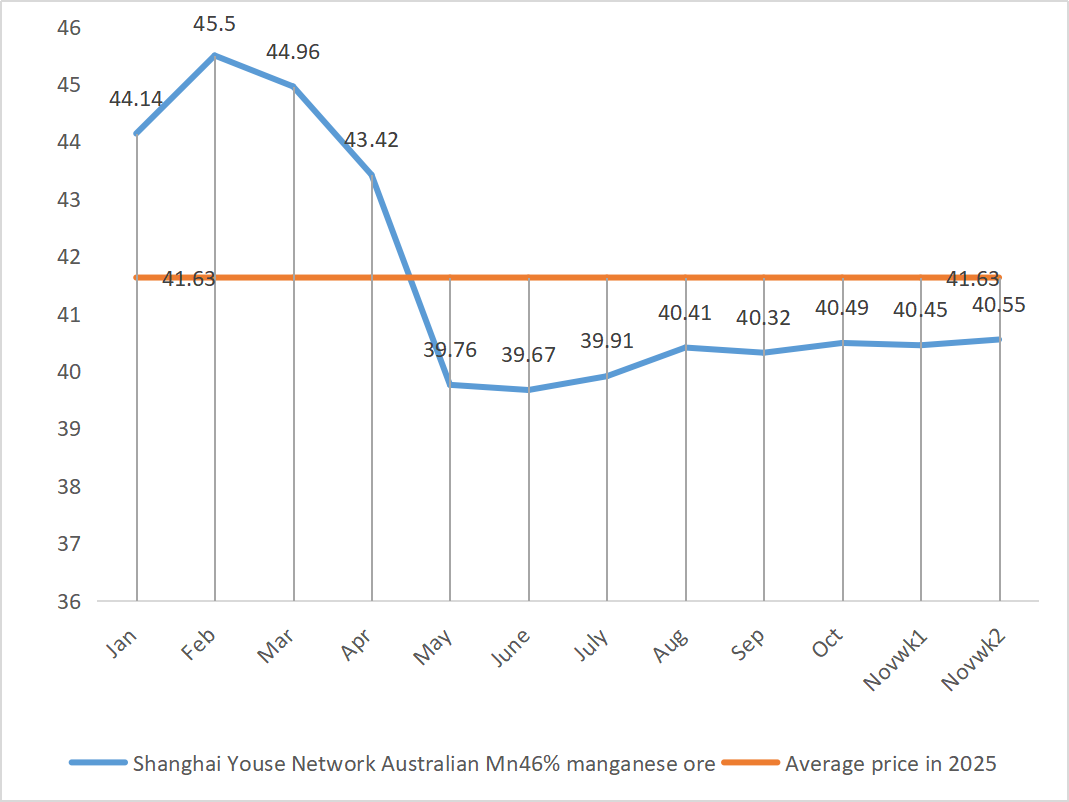

| Capacity utilization rate of titanium dioxide manufacturers | % |

77.02 |

76.04 |

↓0.98 |

77.68 |

76.53 |

↓1.15 |

1)Zinc sulfate

① Raw materials: Zinc hypooxide: The transaction coefficient keeps hitting new highs for the year.

In terms of zinc prices, macroscopically, the market is concerned that the release of a large amount of economic data after the end of the shutdown will affect subsequent interest rate decisions, and the dollar index is under pressure, supporting metal prices; The fundamental export window is still open. Coupled with the recently falling processing fees for zinc concentrate and the expected lower-than-expected output of zinc ingots, multiple factors still provide some support for the bottom of zinc prices. The online price of zinc is expected to be 22,600 yuan per ton next week. ② Sulfuric acid prices are stable at high levels across the country. Soda ash: Prices were stable this week.

On Monday, the operating rate of water zinc sulfate producers was 63%, down 16% from the previous week, and the capacity utilization rate was 66%, down 1% from the previous week. On the supply side: Driven by macro policies in the first half of the year, customers’ concentrated purchases were relatively abundant, resulting in a sluggish current market demand and a slower delivery pace for manufacturers. In the short term, high raw material costs form a rigid support, and the probability of a sharp price drop is not high; In the medium term, affected by the slowdown in exports and the lackluster domestic demand, manufacturers continue to accumulate inventories passively, which will significantly suppress the upward momentum of prices. It is expected that prices will remain stable with narrow fluctuations. It is recommended to purchase on demand.

2)Manganese sulfate

In terms of raw materials: ① Manganese ore prices remain stable at a high level.

② Sulfuric acid remained stable at a high level this week.

This week, the operating rate of manganese sulfate producers was 85%, unchanged from the previous week, and the capacity utilization rate was 57%, down 1% from the previous week. Major manufacturers’ orders are scheduled until early December. Quotations for manganese sulfate rose this week, mainly due to the continuous increase in the price of raw material sulfuric acid, which led to a slight increase in costs. The current manganese sulfate market is in a state of “rising costs, stable demand, and abundant supply”. The continuous increase in costs is disrupting the original balance, and it is expected that prices will rise steadily. Customers are advised to purchase on demand.

3)Ferrous sulfate

Raw materials: As a by-product of titanium dioxide, its supply is constrained by the low operating rate of titanium dioxide in the main industry. Meanwhile, the stable demand from the lithium iron phosphate industry has squeezed the share flowing to the feed industry, resulting in a long-term tight supply of feed-grade ferrous sulfate.

This week, the operating rate of ferrous sulfate manufacturers was 75%, remaining the same as the previous week. Due to the maintenance of some manufacturers, the capacity utilization rate decreased by 4% to 20% compared with the previous week. Manufacturers have scheduled their orders until the first ten days of December. As terminal inventories are gradually digested, small and medium-sized households and traders are inquiring about purchases, and prices remain relatively high. Costs and supply structures support prices, and overall purchases are still mainly based on demand.

4)Copper sulfate/basic copper chloride

Raw materials: Codelco, the state-owned copper company of Chile, saw its output fall 7 percent in September, which also provided support for copper prices, according to data from the Chilean Copper Industry commission (Cochilco). Output from the Glencore and Anglo American joint mine fell 26 percent, while output from BHP’s Escondida mine rose 17 percent. The prospect of a supply shortage for next year has supported copper prices, and supply disruptions at several mines are expected to affect copper concentrate production.

On the macro side, Fed officials’ hawkish stance directly debunked investors’ illusions of easing policy, and this uncertainty dealt a fatal blow to risky assets. Domestically, the spot market has performed poorly, with average market activity and a lack of unilateral drivers for prices. As the off-season atmosphere intensifies, downstream demand is showing a weak trend, and the latest data released by the National Bureau of Statistics indicates that the domestic economy is generally running well, to some extent easing the pessimism in some markets. Overall, despite some disruptions on the supply side, the weak demand situation has not been fundamentally changed. Coupled with factors such as the sluggish U.S. stock market and weakened expectations of interest rate cuts, it is expected that copper prices will fluctuate at a high level with weakness in the short term. Copper price range for the week: 85,900-86,000 yuan per ton.

Etching solution: Some upstream raw material manufacturers have accelerated capital turnover by deep processing etching solution into sponge copper or copper hydroxide, and the proportion of raw materials sold to the copper sulfate industry has narrowed. The tight raw material situation has persisted for a long time, and the transaction coefficient has continued to rise, forming a rigid cost support for the copper sulfate price, making it difficult for the price to fall sharply.

Customers are advised to stock up at the right time when copper prices fall back to a relatively low level based on their own inventories.

5)Magnesium sulfate/magnesium oxide

In terms of raw materials: Currently, sulfuric acid in the north is stable at a high level.

Due to the control of magnesite resources, quota restrictions and environmental rectification, many enterprises are producing based on sales. In September and October, many enterprises with an annual output of less than 100,000 tons were forced to suspend production for transformation due to the capacity replacement policy. There are no concentrated resumption actions in early November, and short-term productivity is unlikely to increase significantly. The price of sulfuric acid has risen, and the prices of magnesium sulfate and magnesium oxide are likely to increase slightly in the short term. It is recommended to stock up appropriately.

6)Calcium iodate

Raw materials: The domestic iodine market is stable at present, the supply of imported refined iodine from Chile is stable, and the production of iodide manufacturers is stable.

The price of refined iodine rose slightly in the fourth quarter, the supply of calcium iodate was tight, and some iodide manufacturers halted or limited production. It is expected that the general tone of a steady and slight increase in iodide prices will remain unchanged. It is recommended to stock up appropriately.

7)Sodium selenite

In terms of raw materials: The price of diselenium rose and then stabilized. Market insiders said that the selenium market price was stable with an upward trend, the trading activity was average, and the price was expected to remain strong in the later period. Sodium selenite producers say demand is weak, costs are rising, orders are increasing, and quotations are slightly lowered this week. Buy on demand.

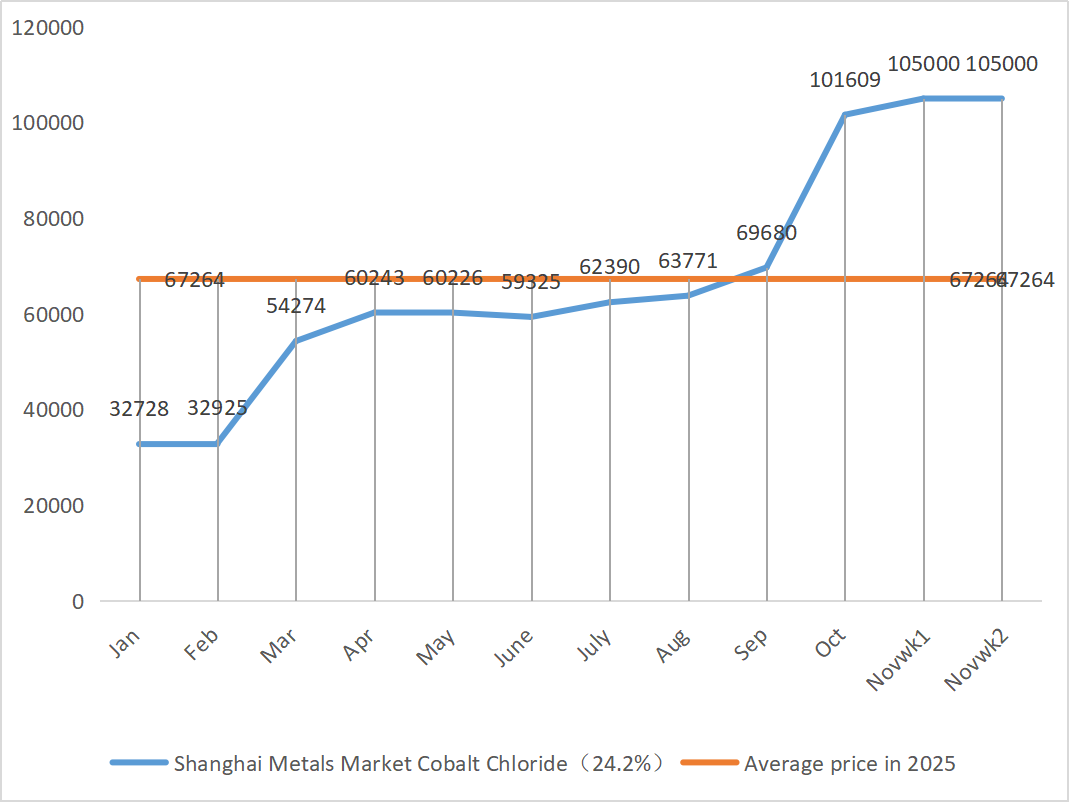

8)Cobalt chloride

This week, cobalt chloride producers’ operating rate was 67%, down 33% from the previous week, and capacity utilization rate was 29%, down 15% from the previous week. Manufacturers’ quotations remained stable this week. The steady pace of shipments by upstream manufacturers and traders has eased the tight market situation, providing a foundation for stabilizing prices. Demand continues the wait-and-see pattern seen last week. Downstream companies, with prices stable, have limited purchasing intentions and are mostly replenishing inventories as needed. The wait-and-see sentiment in the market persists. Due to the firm operation of raw materials, the cost support of cobalt chloride raw materials is strengthened, and it is expected that prices will remain high and stable in the later period.

9)Cobalt salts/potassium chloride/potassium carbonate/calcium formate/iodide

1. Cobalt salts: Raw material costs: Some companies accepted old inventories at low prices from traders, while others began to try to take over new inventories at high prices from smelters, pushing up overall transaction prices. The current market is still in a stage of supply and demand game, and price differences between upstream and downstream remain. It is expected that the price of cobalt sulfate will remain stable in the short term. Once the downstream gradually digests the current price and initiates a new round of purchases, the price of cobalt salt is expected to resume its upward channel.

2. Potassium chloride: After the Nanjing phosphate and compound fertilizer conference, the fertilizer market showed an upward trend. The port stock of imported potassium rose slowly, and downstream demand was released slowly. Major traders such as Sinochem did not sell and intended to push up prices. Pay attention to the port stock quantity and relevant policies in the near future and stock up appropriately. It is recommended to stock up appropriately.

3. Calcium formate prices continued to decline this week. Raw formic acid plants resume production and now increase factory production of formic acid, leading to an increase in formic acid capacity and an oversupply. In the long term, calcium formate prices are falling.

4 Iodide prices were stable this week compared to last week.

Post time: Nov-20-2025